Sheet Metal Products

Sheet metal fabrication is a specialized operation which involves making parts from sheet metal with thickness from 0.5 mm to 10 mm. This involves use of variety of cutting machines (like shearing press, laser cutting, waterjet cutting, plasma cutting etc) to get desired shape. They are subsequently bent as per CAD model using forming tools such as press brakes punches, and dies.

Finishing operations include installation of inserts (eg - PEM inserts), welding, and surface finishing operations such as powder coating, electroplating, galvanizing, or other material specific operations.

Laser cutting

In laser cutting a focused output of a high-power laser (CO2 or Fiber) is used for cutting profiles in materials. The action of laser beam on the material either melts, burns, vaporizes away, or blows away by a jet of gas, which results in an edge with a high-quality surface finish. The position of the laser source is determined by CNC (computer numerical control) system, which in turn is controlled by 2D profile of the part.

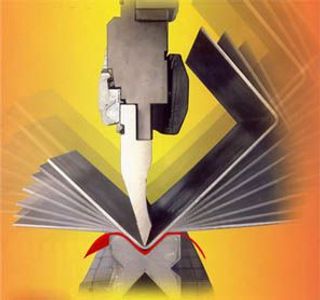

Waterjet cutting

Waterjet cutting involves using high-pressure jet of water mixed with abrasives to cut desired shapes in sheet metals. In water jet cutting, the movement of the jet nozzle is controlled by CNC (Computer Numerical Control) systems, which in-turn is programmed through special software. As compared to laser cutting or plasma gas cutting, water jet cutting does not increase the surface temperature of the workpiece. As a result, metals can be cut without compromising internal structure of the material; hence there is no Heat Affected Zone (HAZ). This also makes it possible to cut wide variety of materials like metals, composites, ceramics (glass, stone, tiles etc), plastics etc.

Our machines can cut sharp corners, holes, and complex shapes with small inner radii with very an accuracy of ± 0.05 mm (±0.002") for most materials.

Stamping

In sheet metal stamping, a blank piece or coiled sheet is placed in a stamping press, where a stamping tool (or die) in the shape of the part is pressed into and through the material to create a net-shape part.

Custom sheet metal stamping includes operations such as blanking, punching, bending, drawing, embossing, and others. Each process is performed using CAD/CAM designed tools that provide the precision required for complex parts.

Press Brake Operations

A press brake is a machine tool for bending sheet metal workpiece. During the operation, the workpiece is held between a matching punch and die. CNC press brake realizes bending function by controlling slider stroke and back gauge.

Copyright © 2024 Spline Curves - All Rights Reserved